- Suprem Quality Components For Vacuum Technology

- CONTACT

Quality Control

Home / Quality Control

How Do We Do Inspection For The Materials

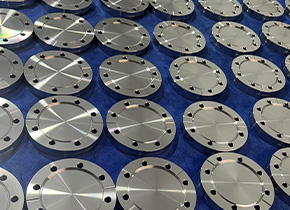

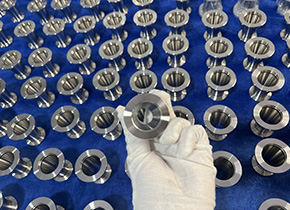

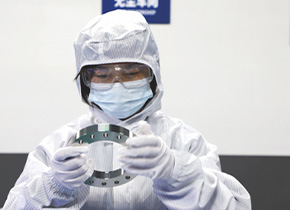

Making sure the finished products of vacuum valves and component's with less trouble and more safety, Ruijia is striving to a perfect quality inspection system.

Visual Testing

Ultrasonic Cleaning

3D Design

Cleaning and Visual Testing

PMI Material Testing

Helium Leakage Testing

Helium Leakage Testing

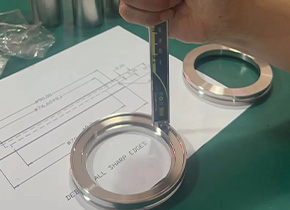

Dimension Inspection

Dimension Inspection

Dimension Inspection

Wall Thickness Test

Laser Marking

For Raw Materials

- Material control from raw materials. For raw material checking, we check 100% by chemical liquid. Any property mistakes would be rejected.

- Sand hole inspection after raw materials are machining before polishing.

- Carbon component report can be provided if needed

- Mechanics test report can be provided if needed

For New Products

- 2nos of new samples to be checked against technical drawing. Testing report is provided to customers before bulk production.

For Finished Products

- For valves, pressure testing and temperature testing is required for each valve.

- After we get the finished products, we do helium leakage test, and check surface roughness, thickness equality, roundness, size measurement and sand holes again.

- For all finished products, the checking quantity is not less than 10% of total quantity.

- Before shipment, we check for the quantity of each product in order to find out any missing quantity or wrong product.

- Finally, we use strong package to prevent the products from any damages.

What Machines We Use To Inspect The Materials

| To Check The Chemical | Stainless Steel Spectrometer |

| To Check The Surface Roughness | Ra Roughness Instrument |

| To Check The Roundness | Vernier Caliper |

| To Check The Thickness | Micrometer, Thickness Gauge |

| To Check The Straightness | Horizontal And Vertical Scale |

| To Check The Pressure | Pressure Testing Machine |

| To Check The Leaking | Hydraulic Pressure Machine |

Forging/Finishing/Sales One-Stop Service

Forging Factory1

4 production lines, 160 tons, 300 tons, 400 tons, 630 tons equipment forging 1--10 inch joints,flanges, adapters,etc

Forging Factory2

4 production lines, 400 tons, 630 tons, 800 tons, 1000 tons forging machines mainly forging butterfly valve bodies, check valve bodies, unions, hose joints and other non-standard parts

Punching Factory

4 production lines with a total production area of 50,000 square meters! The company's products are exported to more than 70 countries and regions!

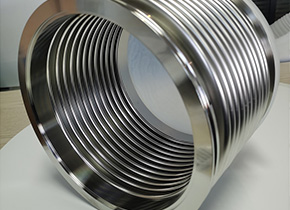

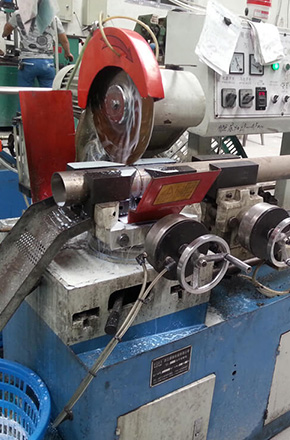

Hardware Facilities

We have high-precision CNC processing equipment from home and abroad, large processing equipment, horizontal machining center, five-axis machining center, large lathe, gantry pentahedron machining center. We have three-coordinate measuring machine, projector, helium leak detector and other measuring instruments. The company is good at the fine processing of stainless steel and aluminum, and has rich experience in the processing and manufacturing of cavities and pipelines in semiconductor, liquid products and photovoltaic industries.

| Large Gantry Machining Center 4200*3200*1400x1 | Cnc Machine Tools 1600*800x30 | Cnc Machine Tools 1200*1500x3 |

| Various Cnc Machine Toolsx1 | Various Machining Centersx6 | Various Tig Welding Machinesx2 |

| Helium Leak Detectorx1 | Three-Coordinate Measuring Machinex9 | Material Analyzerx1 |

Five-Axis Machine Tools

Cutting Machine

Bellows welding

Spectrometer detection

CNC Machine Tools

CNC Machine factory

Gantry machining center

Production workshop