Comparing KF, ISO, CF and ASA flanges

Today I’d like to share a mini-tutorial on vacuum flanges. There are numerous flanges in the world for all types of applications such as steam or liquids, but vacuum flanges have their own unique designs and designations.

The most common vacuum flanges are the KF Flange, the ISO Flange, the CF Flange.

KF Flanges

They are manufactured according to the DIN 28403/ISO 2861 standard. These are sexless flanges, meaning that both sides of the connection are identical and there are no O-ring grooves cut into the flanges.

The standard sizes are KF10, KF16, KF25, KF40 and KF50. Less common are the KF20 and KF32 sizes.

This flange system is also known by several other names such as NW, QF, DIN, and ISO-KF, but all of these flanges are the same.

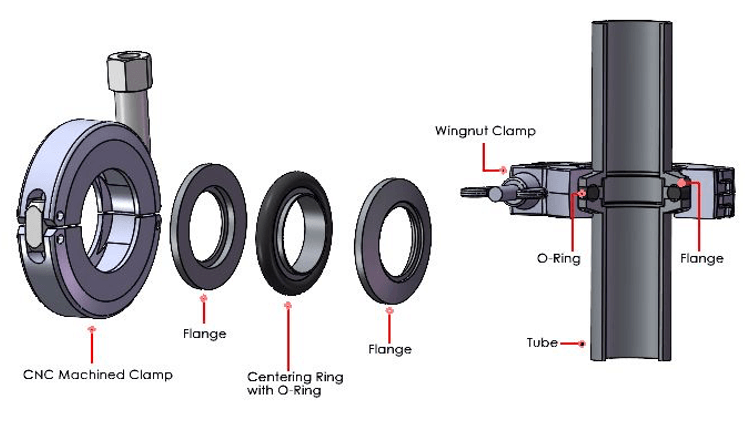

The principle of operation is this: a centering ring holding an O-ring is placed between the two flanges and then the flanges are aligned and brought close together. The wing nut clamp (chain clamps are also available) is placed around the two flange faces and the wing nut is tightened. The two flange faces are squeezed toward one another, thus compressing the O-ring.

These flanges are used in the pressure range from atmosphere to as low as 1×10-8Torr or mbar. The operating and bakeout temperature range depends upon the O-ring material. The most common O-ring material is FKM (Viton-A) which is suitable for the operating temperature range of 0 to 180 deg C and can be exposed to short-term temperatures in the range of -26 to 204 deg C. The leakage and permeability rate of these flanges with FKM is 1×10-9std cc/sec of Helium.

The most common material for these flanges is 304/304L stainless steel, but other materials such as 316L, 316LN, and 6061 aluminum are available as well.

ISO Flanges

Another metric flange that is larger than the KF flanges are the ISO flanges. Similar to the KF flanges they use a centering ring for sealing. They are manufactured according to the DIN 28404/ISO 1609 standard. These are sexless flanges; however, in some cases one of the two flanges will have tapped holes and then the two flanges will not be identical.

The standard sizes are ISO 63, ISO 100, ISO 160, ISO 200, ISO 250, ISO 320, ISO 400, ISO 500 and ISO 630.

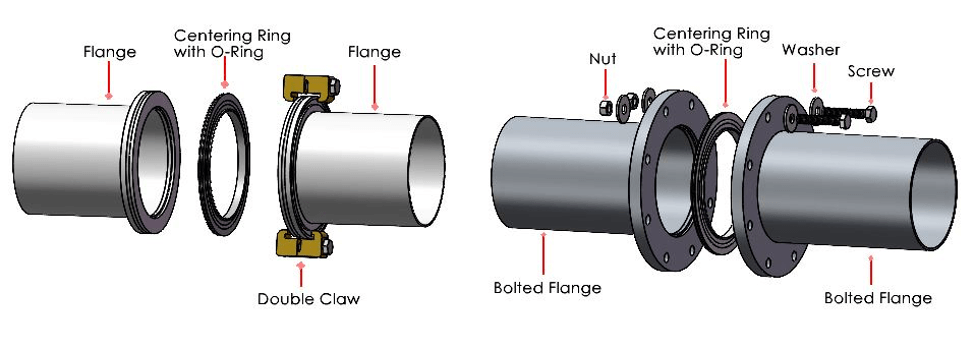

There are two different methods to join the flanges together: 1. Bolts (ISO-F) or 2. Claw clamps (ISO-K). These two flanges look very different, yet they can be joined together by using a half-claw clamp. The naming conventions can be a little bit confusing because the KF flanges above are often called ISO-KF flanges and the two types of larger ISO flanges are ISO-K and ISO-F.

ISO-K flanges have a groove cut into the back of the flange so that a claw clamp can grab ahold of it. Because the letter “K” sounds the same as a “C” it can be helpful to remember that ISO-K requires a Claw Clamp.

ISO-F flanges have holes into the flange that can be used to bolt the two flanges together. These holes most commonly are through holes where a bolt is placed through both flanges; however, the holes can also be tapped where there is no access to place a nut (or nut ring) behind one of the flanges. It can be helpful to remember the ISO-F flange is flatand there is no groove for a claw clamp.

The principle of operation is this: A centering ring that holds an O-ring is placed between the two flanges and then the flanges are aligned and brought close together. The flanges are then joined by claw clamps (for and ISO-K), bolts (for and ISO-F) or with a half claw clamp (when joining an ISO-K to an ISO-F). In each case, as the bolts are tightened the centering ring is compressed making a leak-tight seal.

CF Flanges

The term CF originally came from the name Conflat Flange. However, the word Conflat was a trademark of the Varian Corporation and the flanges became so popular that many companies are making them and using them. So, while they can be referred to as a conflat flange the shortened name CF is more widely used.

A CF flange uses a metal seal and is designed for higher vacuum applications where the permeability of an O-ring is significant to the gas load. Because all the parts are metal they can also be used when a bakeout is required at a higher temperature.

CF Flanges are designed so no gasses can pass through the flanged joint, including helium which is used for leak testing.

The flange size is normally specified by the O.D. of the flange in inches. This is very different from KF and ISO flanges. The common sizes are CF1.33, CF2.75, CF4.50, CF6.00, CF8.00, CF10.00, CF12.00, CF14.00 and CF16.50. Other sizes that are less frequently used are CF2.12, CF3.38, CF4.62, CF6.75 and CF13.25. These are manufactured according to ISO specification ISO 3669-2.

These are sexless flanges, but for design purposes it is important to pay attention as to which holes are tapped and which are through, or the flanges may not bolt together.

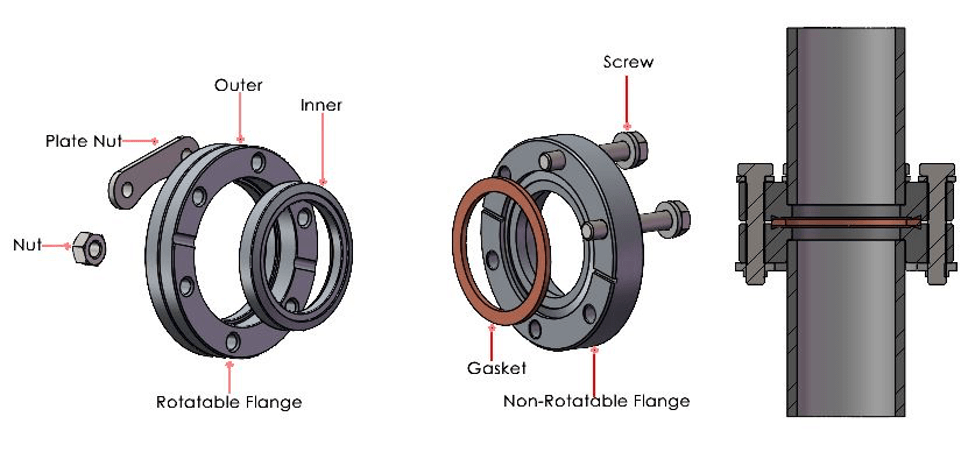

The principle of operation is this: A knife edge is machined into both of the mating flanges. Then, a metal gasket made from a softer material (commonly copper) is placed between the two flanges. As the bolts are tightened, the knife edges cut into copper on both sides, making a leak-tight seal. Similar to the ISO Flanges, 2-piece rotatable CF Flanges are available. The pictorial below shows a rotatable flange on the left.

These flanges are used in the pressure range from atmosphere to as low as 1×10-12Torr or mbar, and the maximum bake out temperature is 842 degrees F (450 degrees C) with the standard copper gaskets.

Provide samples

Provide samples OEM customization

OEM customization Low MOQ

Low MOQ Timely response, online 24 hours a day

Timely response, online 24 hours a day Urgent orders, priority production

Urgent orders, priority production